Landscape of direct-to-garment

printing keeps expanding into commercial and industrial domains

Digital fabric printing is quite viable in the graphic arts industry today with its prospect growing and expanding into new sectors. The technology has reached the direct-to-garment (DTG) printing sector, gaining a new ground for ground-breaking applications. DTG printing is setting new trends in both commercial and industrial domains.

When we look at the global DTG printing market, T-shirt printing represents around nine percent of it. The market is quite big and growing exponentially worldwide. For instance, in North America, the region’s current DTG printing market is valued at $2.5 billion and expected to grow at 10.5 percent CAGR by 2021. Millennial population is the driving force in this niche market. These young people hook to mass customisation and increased personalisation, which in turn fuel the growth in short-run DTG printing in the market.

When we look at the global DTG printing market, T-shirt printing represents around nine percent of it. The market is quite big and growing exponentially worldwide. For instance, in North America, the region’s current DTG printing market is valued at $2.5 billion and expected to grow at 10.5 percent CAGR by 2021. Millennial population is the driving force in this niche market. These young people hook to mass customisation and increased personalisation, which in turn fuel the growth in short-run DTG printing in the market.

Key trends

Vibrancy in the DTG printing is driven by a new market thrust which producers and suppliers call it phenomenal. From a supply chain perspective, mass customisation in T-shirts and other wearable garments creates the need for a toolset that enables short-run manufacturing. This development helps suppliers achieve fast turnaround, minimise waste and reduce inventory. Demand for decorated T-shirts is on the rise.

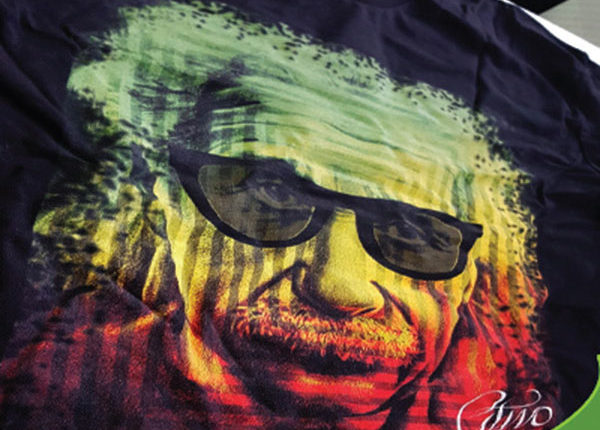

Personalisation is another growing aspect in DTG printing market. Young consumers have strong desire for individual self-expression. They are generally influenced by popular icons or celebrities or current events. They use clothing to express themselves. This fuels the need for personalised DTG printing. Apart from being a material for personalised and innovative graphics, textile is such an eco-friendly printing material that has low impact on environment. After all, the workflow tools and ease-of-use of DTG machines create growth potential in the new market segments.

Soft signage

Today, it’s a well-known fact that the scope of DTG printing is widening. The technology is a viable and reliable method for varieties of soft signage applications, which include long-lasting, high-quality, washable signage graphics, home décor and others comprising technical fabric prints. When it comes to cost effectiveness in DTG process, there are certain factors that are vital. The factors include advancements in printheads, ink, pre-treatment options and printing machines. Printed textile or garment graphics are light weight, which is why they are ease of transport and more cost effective for short-run solutions.

In the textile printing market, DTG represents a growing component. With this technology, finished garments are loaded onto the printer’s platen to accommodate a multitude of T-shirt sizes and even edge-to-edge printing. DTG printing can be used with white or coloured garments, but coloured garments will often require pre-treatment and a base of white ink where the colour will go.

Growing landscape

DTG printing is most advanced and growing landscape being fuelled by growing consumer interest. The signage expos in India or abroad have been witnessing evidence of continued advancements in DTG, encompassing the low-end commercial market as well as the high-volume industrial market.

When we look at the DTG printer market, the range of printers available includes both commercial and industrial systems as well as a few sub-segments within each category based on print volume and price.

Popular printers

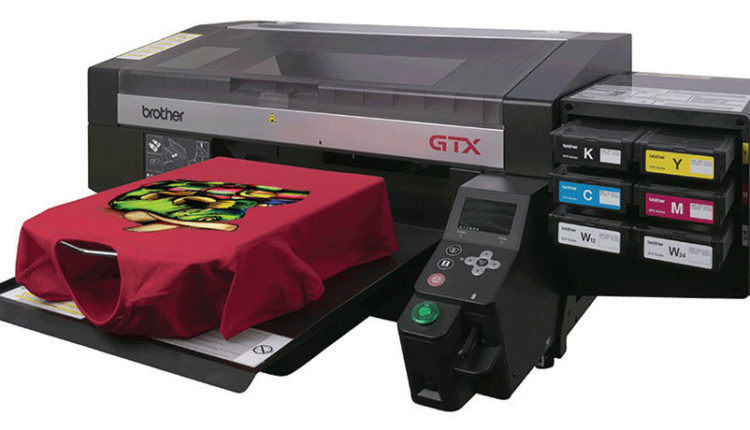

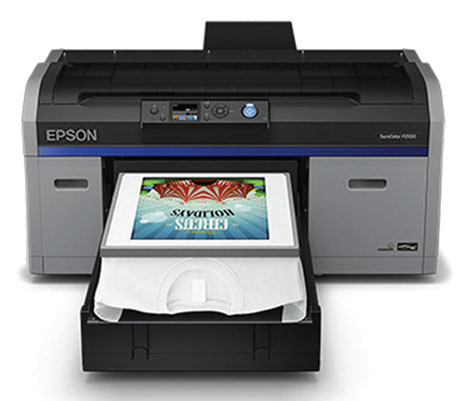

Companies engaging in DTG printing rely on several key products to accommodate their production needs. These include an ever-growing array of printers that support retail over-the-counter printing for small commercial businesses as well as industrial and hybrid printing. The high-end industrial printers include those included in the range of printers based on digital and analogue technologies. Over the past few years, there has been tremendous increase in the production of commercial DTG printing systems which are dramatically upgraded in functionality, usability and reliability coupled with a decrease in prices. Some of the popular GTG printers readily available in the Indian market include an array from the manufacturers like Brother, Roland DGA, Kornit Digital and EPSON.

GTX Series of DTG printers from Brother are designed to print T-shirts in a way that would never ever happen before. The printers run at an accelerated print speed, producing seamless designs. With lower maintenance, GTX printers boast of a robust amount of amazing features that redefine the conventional DTG printing into a new standard. The printers make customisation easiest than ever.

EPSON SC F2100 is another versatile DTG printer, which offers an entirely purpose-built system for high-quality prints at production speeds. Developed using the latest advancements in performance imaging, including the company’s PrecisionCore TFP printhead and Epson UltraChrome DG garment ink technology, SC F2100 achieves up to twice the speeds of their previous generation of DTG printers.

In terms of new players in the block, Roland DGA entered the DTG space with its VersaSTUDIO B12 device. Capable to print directly onto cotton T-shirts, apparel, tote bags and other items in minutes from the comfort of desktop, this affordable DTG printer allows PSPs get into the profitable world of custom apparel immediately. Kornit Digital’s portfolio consists of flagship DTG printers including ATLAS and Avalanche POLY PRO printers. On the industrial printing side, some devices can accommodate up to 400 T-shirts per hour.

DTG printing is such a technology that enables PSPs to expand their business opportunities. But it is wise a decision to establish a realistic business before jumping into any new market domain.